Ladder Cable Tray

EPEPK

Ladder Cable Tray Manufacturer in Pakistan Heavy-Duty, Industrial-Grade Cable Management Solutions

A ladder cable tray is one of the most reliable and widely used cable management systems in heavy-duty electrical installations. Designed for strength, ventilation, and long-span support, ladder cable trays are commonly installed in industrial plants, power stations, commercial buildings, and infrastructure projects across Pakistan. As a trusted ladder cable tray manufacturer in Pakistan, Electric Power Engineering specializes in producing high-load cable tray systems that ensure safe cable routing, thermal efficiency, and long-term operational reliability.

Our ladder cable tray systems are engineered for demanding environments where mechanical strength, easy maintenance, and future expandability are essential. From manufacturing facilities and refineries to data centers and renewable energy plants, Electric Power Engineering provides cable tray solutions that perform consistently under real working conditions. We supply ladder cable trays across Lahore, Karachi, Faisalabad, Islamabad, and all major industrial zones of Pakistan.

What Is a Ladder Cable Tray?

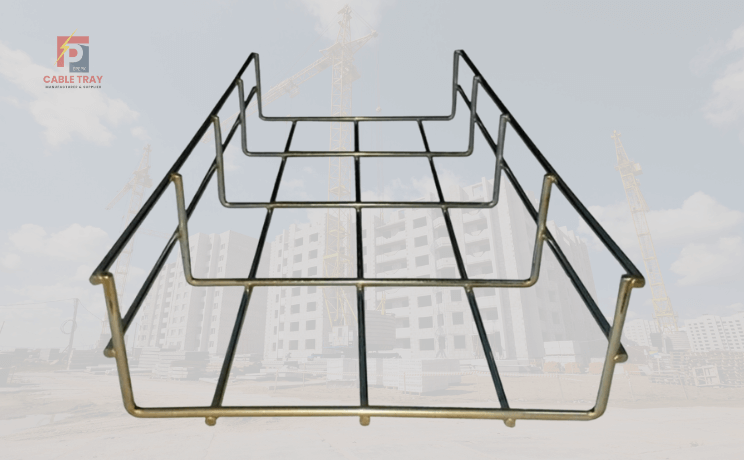

A ladder cable tray is a type of cable support system that consists of two parallel side rails connected by evenly spaced rungs. This ladder-like structure provides high load-bearing capacity, excellent airflow, and easy access to cables, making it ideal for heavy power cables and long cable runs.

Unlike closed or solid-bottom trays, ladder cable trays allow heat to dissipate naturally, reduce cable weight stress, and simplify inspection and maintenance. In Pakistan, ladder cable trays are commonly used in projects where large power cables, long spans, and high mechanical strength are required.

- We use hot dip galvanized steel, stainless steel, and aluminum to ensure durability and resistance to corrosion.

- All our trays are manufactured locally at our state-of-the-art facility, ensuring top quality and quick delivery.

- We manufacture trays according to your project needs — width, thickness, length, and finishes are customizable.

Types of Ladder Cable Trays We Manufacture

Electric Power Engineering, based in Lahore, is trusted by clients nationwide. We’re one of the leading Cable Tray suppliers in Lahore and ship across major cities including Karachi, Islamabad, Faisalabad, and Multan.

- GI Ladder Cable Tray Offers excellent corrosion resistance and strength, making it ideal for supporting heavy-duty cables in industrial environments.

- GI Powder Coated Ladder Cable Tray Benefit: Provides enhanced corrosion protection and aesthetic appeal, suitable for indoor installations with exposure to humidity or mild chemicals.

- MS Powder Coated Cable Tray Cost-effective solution with good durability and rust resistance for indoor or sheltered cable management systems.

- MS Hot Dip Galvanized Ladder Cable Tray, Highly durable and corrosion-resistant, this is the most requested product for outdoor and industrial use.

- SS 304 Cable Tray High resistance to corrosion, heat, and chemical exposure, making it ideal for cleanrooms, food processing plants, and chemical industries.

- Aluminum Ladder Cable Tray Lightweight and rust-free — ideal for commercial and light industrial installations.

Role of Cable Tray Systems in Modern Electrical Infrastructure

Cable tray systems form the backbone of modern electrical and communication networks. They organize, support, and protect cables while maintaining safety, accessibility, and performance. Whether it is a high-voltage industrial facility or a commercial office building, a properly designed cable tray system improves system reliability and reduces maintenance complexity.

Electric Power Engineering manufactures multiple types of cable trays, including ladder cable trays, perforated cable trays, solid-bottom trays, and wire mesh trays. Each design is engineered to serve specific load conditions, environmental exposures, and installation requirements. Among all, ladder cable trays remain the first choice for heavy-duty and long-span applications.

Trusted Ladder Cable Tray Manufacturer in Pakistan Electric Power Engineering

Electric Power Engineering is a leading cable tray manufacturer in Pakistan, serving the industrial, commercial, and power sectors with high-performance cable management systems. Our ladder cable trays are manufactured using premium-grade steel and advanced fabrication processes to ensure dimensional accuracy, mechanical strength, and corrosion resistance.

We do not follow generic production methods. Instead, our engineering team designs every ladder cable tray based on actual project conditions such as cable weight, span length, installation height, and environmental exposure. This practical approach enables us to deliver products that meet real-world performance expectations. Our manufacturing facility follows strict quality controls, material inspections, and finishing standards to ensure that every ladder cable tray we supply performs reliably over long service periods. This commitment to engineering excellence has made Electric Power Engineering a trusted name across Pakistan.

Why Ladder Cable Trays Are Preferred for Heavy-Duty Installations

Ladder cable trays are specifically designed for heavy cable loads and long-span routing. Their open structure reduces material weight while maintaining high structural strength. This design allows for natural heat dissipation, which is essential for high-current power cables.

In industrial environments where cable replacement, upgrades, and inspections are frequent, ladder cable trays provide easy access. Their rung structure allows technicians to route, clamp, and reconfigure cables without dismantling entire sections. In Pakistan’s climate, where heat and dust are common challenges, ladder cable trays perform exceptionally well by preventing heat buildup and reducing moisture retention.

Uses of Ladder Cable Trays in Pakistan

Ladder cable trays are used across a wide range of sectors due to their strength, adaptability, and ease of maintenance.

Industrial Facilities

Manufacturing plants, oil and gas refineries, cement factories, and steel mills use ladder cable trays to support heavy power cables, motor feeders, and control wiring. These environments require trays that can withstand vibration, dust, and high temperatures.

Power Generation and Distribution

Power plants, substations, and transmission facilities rely on ladder cable trays for routing high-voltage cables over long distances. Their open structure prevents overheating and allows for easy cable segregation.

Commercial Buildings

Shopping malls, high-rise buildings, and business centers use ladder trays in service shafts and rooftop installations where large bundles of cables must be supported securely.

Renewable Energy Projects

Solar power plants and wind energy facilities in Pakistan use ladder cable trays for DC and AC cable routing under outdoor conditions. Their strength and corrosion-resistant finishes make them suitable for harsh climates.

Ladder Cable Tray Sizes and Custom Manufacturing

Electric Power Engineering offers both standard and fully customized ladder cable tray solutions. Every project has unique requirements, and our manufacturing process allows us to tailor tray dimensions, thickness, and finishes accordingly.

Load-Based Engineering Design

The load capacity of a ladder cable tray depends on span length, side rail thickness, and rung spacing. Our engineering team calculates these parameters precisely to prevent sagging, deformation, or failure.

Installation-Specific Customization

We provide ladder cable trays that can be ceiling-mounted, wall-mounted, or floor-supported. Custom bends, vertical risers, reducers, and junctions are fabricated to ensure seamless installation.

Ladder Cable Tray vs Perforated Cable Tray

Many buyers ask whether ladder cable trays or perforated cable trays are better. The answer depends on the application. Ladder cable trays are designed for heavy power cables and long spans. Their open structure provides excellent ventilation and high mechanical strength. Perforated cable trays, on the other hand, offer continuous bottom support and are more suitable for smaller cables and mixed wiring systems.

For most heavy-duty industrial projects in Pakistan, ladder cable trays are preferred because of their superior load-bearing capacity and thermal performance.

How to Choose the Right Ladder Cable Tray for Your Project

Selecting the correct ladder cable tray requires an understanding of cable weight, environmental conditions, and future expansion needs.

Cable Load and Span Length

Heavy cables and long spans require thicker side rails and reinforced rungs. Undersized trays can deform over time, leading to safety risks.

Indoor vs Outdoor Installation

Indoor installations typically use powder-coated or pre-galvanized trays, while outdoor and industrial environments require hot-dip galvanized trays for corrosion protection.

Future Cable Expansion

It is always recommended to choose a tray width that allows additional cables to be added later without overcrowding.

Local Ladder Cable Tray Supplier Across Pakistan

Electric Power Engineering supplies ladder cable trays directly from our manufacturing facility to all major cities of Pakistan. Our logistics network allows us to deliver quickly and safely to Lahore, Karachi, Faisalabad, Islamabad, Multan, Peshawar, and beyond.

Working directly with a manufacturer ensures better pricing, strict quality control, and complete design customization. This approach eliminates the risks associated with resellers and generic suppliers.

Price of Ladder Cable Tray in Pakistan

The price of ladder cable trays in Pakistan depends on multiple factors such as material type, thickness, width, finishing, and order volume. Hot-dip galvanized trays generally cost more than pre-galvanized or powder-coated options due to their superior corrosion resistance. Electric Power Engineering provides transparent pricing based on actual material and fabrication costs. Our team also offers technical consultation to ensure that customers do not overpay for unnecessary specifications.

Why Electric Power Engineering Is a Trusted Cable Tray Brand

Our reputation is built on engineering integrity, material quality, and long-term customer relationships. We do not just sell products; we deliver engineered solutions. Every ladder cable tray we manufacture is tested for dimensional accuracy, coating thickness, and structural stability.

Get a quote

Contact a Reliable Ladder Cable Tray Manufacturer in Pakistan

If you are planning an industrial, commercial, or power project and need a dependable cable tray system, our technical team is ready to assist you. From design consultation to custom fabrication and nationwide delivery, Electric Power Engineering provides complete cable management solutions across Pakistan.

Powder Coated Cable Tray

Perforated Cable Tray

Wire Mesh Cable Tray

sales@epepk.com

0300-9444-973