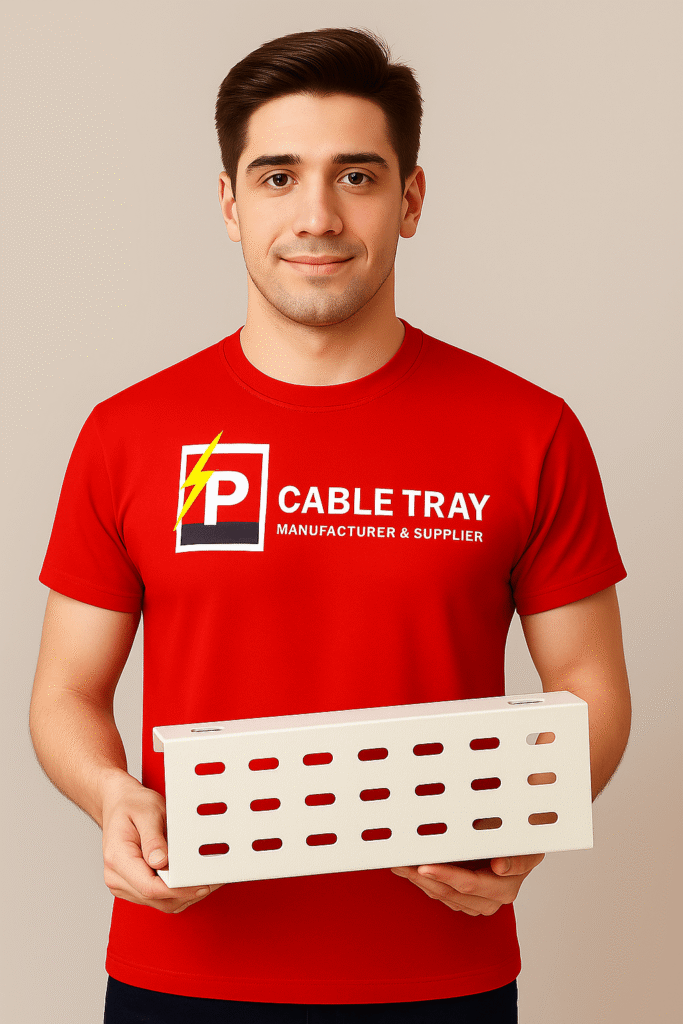

Powder Coated Cable Tray

EPEPK

Powder Coated Cable Tray in Pakistan Durable, Corrosion-Resistant Cable Management Solutions

A powder coated cable tray is one of the most reliable and visually refined cable management systems used in modern electrical installations. Designed to offer superior corrosion resistance, long service life, and a clean industrial finish, powder coated cable trays are widely used in commercial buildings, industrial facilities, data centers, hospitals, and infrastructure projects across Pakistan.

As a leading cable tray manufacturer in Pakistan, Electric Power Engineering specializes in manufacturing premium-quality powder coated cable tray systems from its Lahore-based factory, supplying custom-engineered solutions to clients nationwide. Our cable trays are designed to meet both functional and aesthetic requirements while ensuring long-term safety and durability.

What Is a Powder Coated Cable Tray?

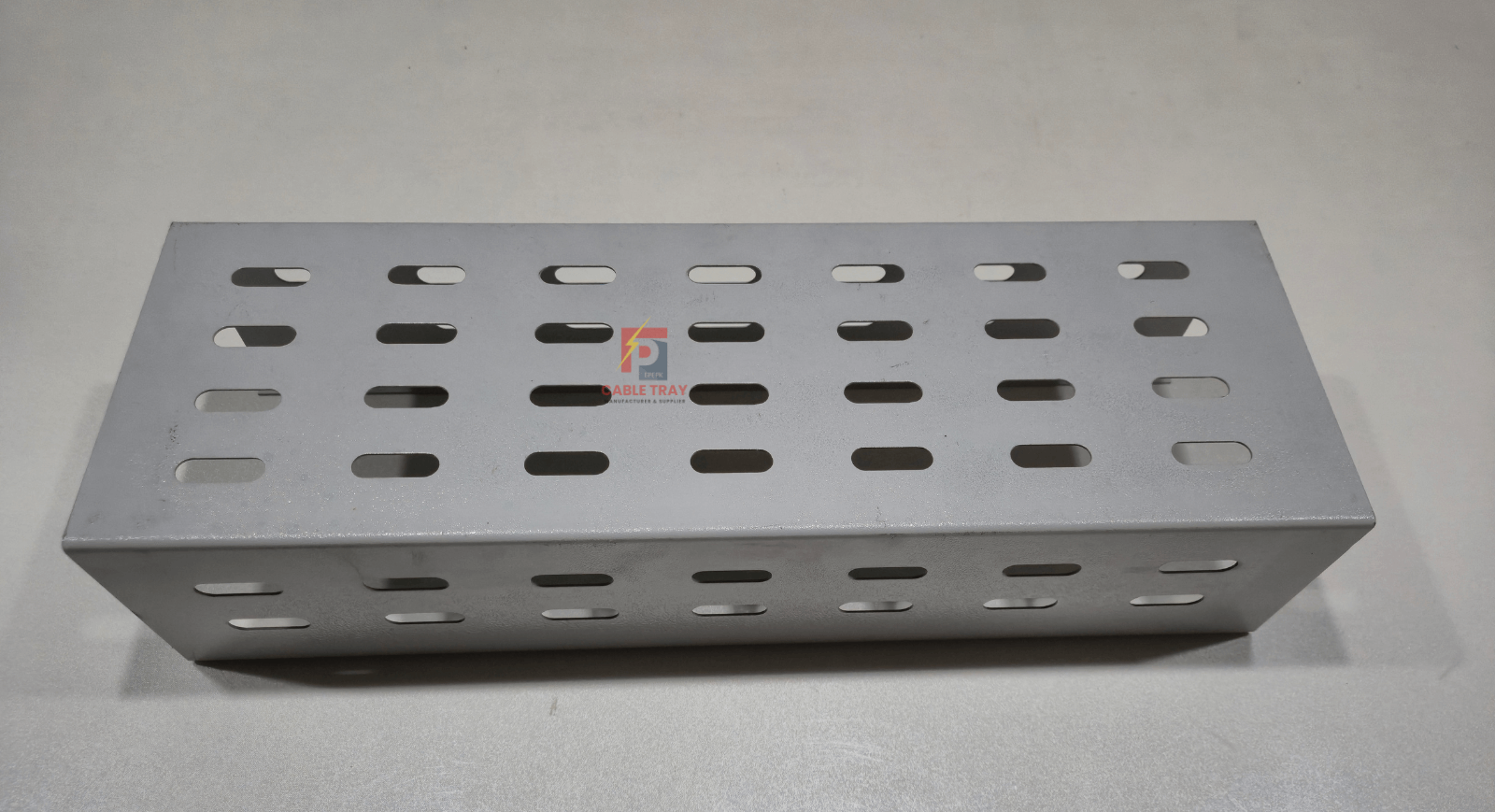

A powder coated cable tray is a metal cable management system that is coated with a dry powder paint using an electrostatic process and then cured under heat. This creates a smooth, uniform, and highly durable protective layer that resists corrosion, moisture, chemicals, and environmental damage.

Cable Tray Types Available in Powder Coated Finish

We offer various types of Cable Trays with Powder Coating and other finishes that suit different industrial needs. Unlike traditional painted or galvanized trays, powder coated cable trays offer better surface adhesion, consistent color finish, and enhanced scratch resistance. In Pakistan’s diverse climate ranging from high humidity to extreme heat powder coated cable trays provide a long-lasting and low-maintenance solution. Here’s a look at our range:

- GI Powder Coated Cable Tray

- MS Powder Coated Cable Tray

- SS 304 Cable Tray (Stainless Steel)

- MS Hot-Dip Galvanized Cable Tray (After Fabrication)

Role of Cable Tray Systems in Modern Electrical Infrastructure

Cable tray systems are a core part of modern electrical design. They support, organize, and protect electrical cables, control wiring, and data cables while maintaining accessibility for future maintenance and upgrades.

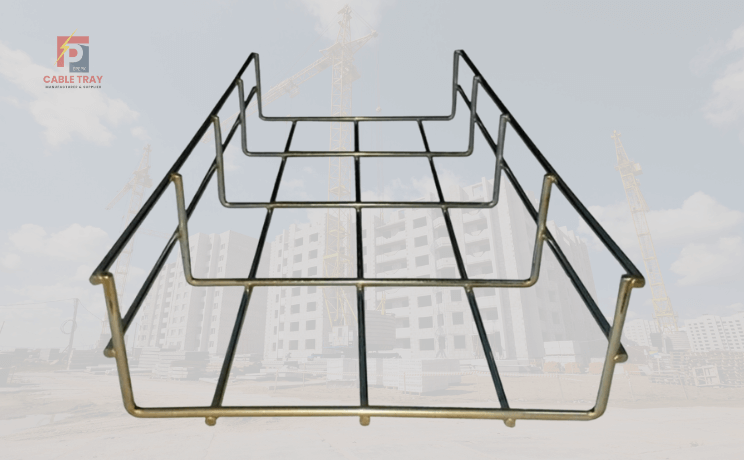

In industrial and commercial projects, choosing the right cable tray system directly impacts safety, system performance, and long-term reliability. Powder coated cable trays combine structural strength with corrosion resistance, making them ideal for visible installations where aesthetics and durability both matter. Electric Power Engineering manufactures a complete range of cable tray systems, including powder coated cable trays, perforated cable trays, ladder cable trays, solid-bottom trays, and wire mesh trays.

Trusted Powder Coated Cable Tray Manufacturer in Pakistan

Electric Power Engineering is a trusted cable tray manufacturer in Pakistan, serving the electrical, industrial, and construction sectors for years. Our production facility in Lahore is equipped with modern fabrication machinery, precision cutting tools, and a high-quality powder coating plant.

We follow a strict manufacturing process that ensures:

Uniform coating thickness

Strong surface adhesion

Resistance to chipping and peeling

Long-term color stability

High mechanical strength

Unlike imported or low-quality trays, our powder coated cable trays are manufactured using high-grade steel, ensuring consistent performance even in demanding environments.

Why Powder Coated Cable Trays Are Preferred

Powder coated cable trays offer several advantages over traditional finishes.

They provide excellent resistance to corrosion, especially in humid, dusty, or chemically exposed environments. This makes them suitable for hospitals, pharmaceutical plants, food processing units, and indoor industrial spaces. Powder coating also enhances the visual appearance of the tray. This is important for installations in offices, malls, showrooms, and commercial buildings where exposed cable management systems must look clean and professional. In addition, powder coated cable trays require minimal maintenance, reducing long-term operational costs.

Applications of Powder Coated Cable Trays in Pakistan

Powder coated cable trays are used across a wide range of sectors in Pakistan due to their durability, clean finish, and flexibility.

Commercial Buildings

Shopping malls, corporate offices, educational institutions, and hospitals rely on powder coated cable trays for neat and organized cable routing. Their clean finish blends well with interior designs.

Industrial Facilities

Manufacturing plants and processing units require cable trays that can withstand dust, vibration, and chemical exposure. Powder coating adds an extra protective layer.

Data Centers and IT Infrastructure

Cable management is critical in IT environments. Powder coated trays provide proper ventilation while maintaining a professional appearance.

Residential and Mixed-Use Projects

In modern residential towers and mixed-use developments, visible cable tray installations are increasingly common. Powder coated trays offer both safety and aesthetics.

Powder Coated Cable Tray vs Galvanized Cable Tray

Powder coated cable trays and galvanized cable trays serve different purposes. Galvanized trays are mainly used for heavy-duty outdoor and corrosive environments. Powder coated trays, on the other hand, are ideal for indoor and semi-exposed installations where visual appearance, color consistency, and surface smoothness matter. While galvanized trays provide sacrificial corrosion protection, powder coated trays offer superior finish quality and color options. Many clients in Pakistan choose powder coated cable trays for commercial and architectural projects.

Materials Used in Powder Coated Cable Trays

At Electric Power Engineering, we use premium-grade steel as the base material for our powder coated cable trays. The steel is precision-fabricated and chemically pre-treated before powder application to ensure maximum coating adhesion. The powder coating process involves electrostatic application of the coating powder, followed by curing in a temperature-controlled oven. This creates a uniform, sealed surface that resists corrosion, moisture ingress, and abrasion.

Powder Coated Cable Tray Sizes and Customization

Every project has unique requirements. That is why we offer both standard and custom powder coated cable tray systems.

Our engineering team designs trays based on:

Cable load capacity

Span length

Installation type

Environmental conditions

Aesthetic requirements

We also manufacture accessories such as bends, tees, reducers, risers, and covers to ensure seamless installation.

How to Choose the Right Powder Coated Cable Tray

Choosing the correct powder coated cable tray depends on several factors. The total cable load determines the thickness and side rail height. Longer spans require reinforced profiles to prevent sagging. The installation environment also matters. Areas with moisture or chemical exposure require additional surface treatments before coating. Future expansion should always be considered. Selecting a slightly wider tray allows room for additional cables.

Powder Coated Cable Tray Price in Pakistan

The price of powder coated cable trays in Pakistan depends on multiple variables, including:

Material thickness

Tray width and height

Coating quality

Order volume

Customization level

Electric Power Engineering offers factory-direct pricing with no middlemen. This ensures competitive rates without compromising on quality. Contact us for more details.

Local Cable Tray Manufacturer in Lahore, Supplying All Pakistan

We operate from Lahore, which is one of Pakistan’s major industrial hubs. From here, we supply powder coated cable trays to Karachi, Islamabad, Faisalabad, Multan, Peshawar, and all other cities. Our logistics network ensures safe packaging and timely delivery, even for large industrial orders.

Why Choose Our Powder Coated Cable Trays?

Reliable quality with strict quality control, Available in multiple thicknesses and widths, Strong, durable, and corrosion-resistant, Custom fabrication and fast delivery across Pakistan, Competitive pricing for bulk orders

- GI Powder Coated Cable Tray Made from pre-galvanized steel sheets (GI) Powder coating adds extra rust and corrosion resistance

- MS Powder Coated Cable Tray Manufactured from mild steel (MS) Powder coated to prevent corrosion and improve durability

- MS Hot-Dip Galvanized Cable Tray (After Fabrication) Fabricated first, then fully hot-dip galvanized Provides superior rust protection

Powder Coated Cable Trays for Long Term Reliability

Powder coated cable trays are a long-term investment. Their corrosion resistance, smooth finish, and low maintenance make them ideal for projects where durability and appearance both matter. From commercial buildings to industrial plants, powder coated cable trays provide safe and organized cable routing for years.

Get a quote

Why Choose Electric Power Engineering

We are not just a supplier—we are a manufacturer. This gives us complete control over quality, design, and delivery timelines. Our expertise in cable tray systems, combined with real-world project experience, allows us to recommend the most suitable solutions for each application. We follow industry standards, conduct material inspections, and maintain consistent production quality.

Ladder Cable Tray

Perforated Cable Tray

Wire Mesh Cable Tray

sales@epepk.com

0300-9444-973